WRIKU ‘s core philosophy always provides users with sustainable products and solutions, serving attentively and building quality with professionalism, credibility and integrity Read More

WRIKU ‘s core philosophy always provides users with sustainable products and solutions, serving attentively and building quality with professionalism, credibility and integrity Read More

| Availability: | |

|---|---|

ICS-30A Type Weighing Frame

ICS-30A type weighing frame, no lever, full suspension structure design, stable and reliable, the structure design is basically close to the physical calibration value with chain code calibration, fully enclosed, moisture-proof, dust-proof, anti-corrosion and reducing material accumulation, and will not be used. Problems such as zero point instability caused by knife edge device and bearing device

2017-03-28

Product introduction:

ICS-30A Scale's weighing frame is designed without lever, with fully suspended structure , it is stable and reliable, its structure design is basically close to the physical calibration value with chain code calibration, fully enclosed, moisture-proof, dust-proof, anti-corrosion and reduce material accumulation , there will be no problems such as zero point instability caused by the use of knife-edge devices and bearing devices.

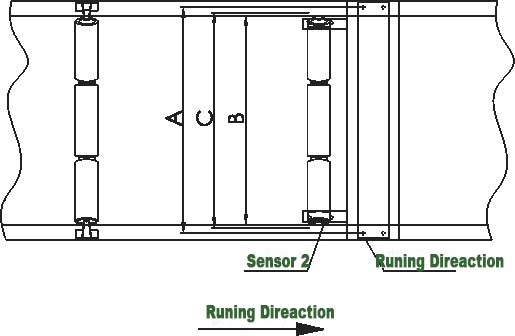

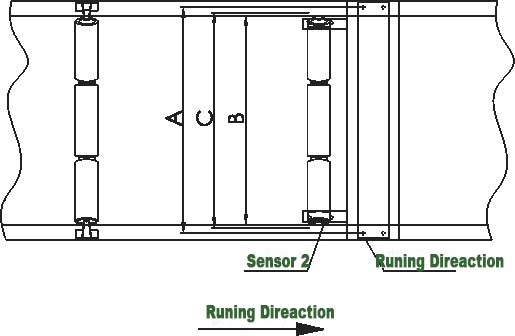

1..During production, the scale body must strictly control the idler spacing, sensor force point and lever fulcrum according to the standard, otherwise the measurement stability of the system cannot be controlled during actual operation. In Figure 1 below we have marked the reference table.

2.The operating environment of the belt scale is relatively complex, such as: belt deviation, uneven material conveying (intermittent conveying in some sites), environmental factors (wind, rain, vibration), and uniform speed of the idle speed of the conveyor belt, all of which will lead to measurement errors. . Our company has experienced more than 10 years of production and on-site experience to overcome one by one, and the products will make corresponding technical adjustments according to on-site use every year, and strive to be the best belt scale.

2.1.★Characteristics of array belt scale:

2.1.1.The box-type structure of the load cell has the anti-eccentric load force and the conveyor deviation measurement stability.

2.1.2. The integrated structure of the main beam protects the sensor from environmental influences, maintenance-free, and no wearing parts.

2.1.3. Remote touch screen full Chinese instrument operation interface.

2.1.4.Built-in black box behavior track encryption program

2.1.5.Leverless fully suspended structure;

2. 1.6.Two pressure sensors;

2.1.7.The weight of the material passing through the roller directly acts on the sensor;

2.1.8 The pressure sensor is adopted, so the scale body has strong resistance to lateral force and effectively balances the measurement deviation caused by uneven materials on the belt.

ICS-30A Type Weighing Frame

ICS-30A type weighing frame, no lever, full suspension structure design, stable and reliable, the structure design is basically close to the physical calibration value with chain code calibration, fully enclosed, moisture-proof, dust-proof, anti-corrosion and reducing material accumulation, and will not be used. Problems such as zero point instability caused by knife edge device and bearing device

2017-03-28

Product introduction:

ICS-30A Scale's weighing frame is designed without lever, with fully suspended structure , it is stable and reliable, its structure design is basically close to the physical calibration value with chain code calibration, fully enclosed, moisture-proof, dust-proof, anti-corrosion and reduce material accumulation , there will be no problems such as zero point instability caused by the use of knife-edge devices and bearing devices.

1..During production, the scale body must strictly control the idler spacing, sensor force point and lever fulcrum according to the standard, otherwise the measurement stability of the system cannot be controlled during actual operation. In Figure 1 below we have marked the reference table.

2.The operating environment of the belt scale is relatively complex, such as: belt deviation, uneven material conveying (intermittent conveying in some sites), environmental factors (wind, rain, vibration), and uniform speed of the idle speed of the conveyor belt, all of which will lead to measurement errors. . Our company has experienced more than 10 years of production and on-site experience to overcome one by one, and the products will make corresponding technical adjustments according to on-site use every year, and strive to be the best belt scale.

2.1.★Characteristics of array belt scale:

2.1.1.The box-type structure of the load cell has the anti-eccentric load force and the conveyor deviation measurement stability.

2.1.2. The integrated structure of the main beam protects the sensor from environmental influences, maintenance-free, and no wearing parts.

2.1.3. Remote touch screen full Chinese instrument operation interface.

2.1.4.Built-in black box behavior track encryption program

2.1.5.Leverless fully suspended structure;

2. 1.6.Two pressure sensors;

2.1.7.The weight of the material passing through the roller directly acts on the sensor;

2.1.8 The pressure sensor is adopted, so the scale body has strong resistance to lateral force and effectively balances the measurement deviation caused by uneven materials on the belt.

Features:

sensor protection compartment design,

integrated design

16MM strip steel longitudinal beam,

4mm square tube spanning beam.

3. Instrument selection and performance indicators

CM-700 Electronic Belt Scale Instrument

HD series dynamic control display is suitable for the occasion of dynamic cumulative measurement of materials. It has the characteristics of high resolution in A/D, fast conversion speed, good long-term stability, strong monitoring ability, and simple use. And has a certain margin, which can be expanded according to user requirements.

Features:

sensor protection compartment design,

integrated design

16MM strip steel longitudinal beam,

4mm square tube spanning beam.

3. Instrument selection and performance indicators

CM-700 Electronic Belt Scale Instrument

HD series dynamic control display is suitable for the occasion of dynamic cumulative measurement of materials. It has the characteristics of high resolution in A/D, fast conversion speed, good long-term stability, strong monitoring ability, and simple use. And has a certain margin, which can be expanded according to user requirements.

| Specification | ||||||||

| Model | Accuracy(%) | Weighing Range(t/h) | Inclined | Sensor Number) | Calculation Roller Number | Pressure Level | trunnion(PC) | Speed Sensore(PC) |

| ICS-14A | ±0.125 | 1-8000 | <6° | 4 | 4 | Suspended | 0 | 1 |

| ICS-14B | ±0.125 | 1-8000 | <17° | 4 | 3 | Suspended | 0 | 1 |

| ICS-17A | ±0.25 | 1-6000 | <17° | 2 | 4 | double lever | 0 | 1 |

| ICS-17B | ±0.25 | 1-4000 | <17° | 2 | 2 | single leverage | 2 | 1 |

| ICS-20A | ±0.5 | 1-8000 | <17° | 1 | 2 | double lever | 2 | 1 |

| ICS-20B | ±0.5 | 1-8000 | <17° | 1 | 1 | single leverage | 2 | 1 |

| ICS-30A | ±0.25 | 1-8000 | <17° | 2 | 1 | Suspended | 0 | 1 |

| ICS-30B | ±0.25 | 1-8000 | <17° | 1 | 1 | Suspended | 0 | 1 |

| ICS-30-2TC-4C | ±0.125 | 1-8000 | <17° | 4 | 2 | Suspended | 0 | 1 |

| SN-XF-4 | ±0.125 | 1-8000 | <6° | 8 | 8 | Suspended | 0 | 1 |

| Specification | ||||||||

| Model | Accuracy(%) | Weighing Range(t/h) | Inclined | Sensor Number) | Calculation Roller Number | Pressure Level | trunnion(PC) | Speed Sensore(PC) |

| ICS-14A | ±0.125 | 1-8000 | <6° | 4 | 4 | Suspended | 0 | 1 |

| ICS-14B | ±0.125 | 1-8000 | <17° | 4 | 3 | Suspended | 0 | 1 |

| ICS-17A | ±0.25 | 1-6000 | <17° | 2 | 4 | double lever | 0 | 1 |

| ICS-17B | ±0.25 | 1-4000 | <17° | 2 | 2 | single leverage | 2 | 1 |

| ICS-20A | ±0.5 | 1-8000 | <17° | 1 | 2 | double lever | 2 | 1 |

| ICS-20B | ±0.5 | 1-8000 | <17° | 1 | 1 | single leverage | 2 | 1 |

| ICS-30A | ±0.25 | 1-8000 | <17° | 2 | 1 | Suspended | 0 | 1 |

| ICS-30B | ±0.25 | 1-8000 | <17° | 1 | 1 | Suspended | 0 | 1 |

| ICS-30-2TC-4C | ±0.125 | 1-8000 | <17° | 4 | 2 | Suspended | 0 | 1 |

| SN-XF-4 | ±0.125 | 1-8000 | <6° | 8 | 8 | Suspended | 0 | 1 |

WEIGHTING DEVICE

◆Comprehensive accuracy: ±0.01%;

◆The display is a four-line screen display, showing the instantaneous flow, cumulative amount, and operating parameters of the belt conveyor;

◆Scrolling menu, can be used for parameter input setting Chinese display, easy to operate;

◆Multiple calibration methods, automatic zero point and interval, automatic zero point tracking;

◆Communication interface (optional): standard RS~232C, RS485 interface.

◆If necessary, it can provide MODBUS, Ethernet communication and other functions.

◆The flow rate that can be set, the software PID adjustment, realizes the DCS automatic batching system control;

◆Multiple input and output ports;

◆Printing interface (printer optional).

◆Easy debugging: Chinese menu, automatic zero calibration, automatic interval calibration, fault self-diagnosis.

◆Data remote transmission:

a Analog quantity: real-time flow through the current signal (4-20mA, optional), the accumulated quantity is output to the remote place through the pulse signal

b digital: transmit all data to the host computer by means of communication;

◆Fault alarm: high flow alarm, low flow alarm, shutdown alarm, external alarm and other alarm signals;

◆Communication function: standard RS232 and standard RS485 interface, baud rate can be adjusted, address can be set, and multiple instruments can be networked;

◆Weighing instrument has two types: panel embedded and wall-mounted, which can meet the different requirements of various sites

Speed Sensor

◆It is connected to a special speed measuring device, which can eliminate the error caused by slippage between the friction wheel and the belt in the usual speed measuring device;

◆Airtight shell, with good shielding performance, good sealing performance, suitable for outdoor installation;

◆Brushless pulse generator, no need to adjust, calibrate or maintain;

◆The latest soft connection technology ensures the speed measurement accuracy more effectively;

◆Speed range: 0.05-4.0m/s

Weighting Sensor

The load cell is resistance strain gauge tension (pressure) force sensor.

◆Nonlinearity: less than 0.05% of rated output;

◆Repeatability: less than 0.03% of rated output;

◆ Hysteresis: less than 0.03% of rated output;

◆Temperature sensitivity: ±0.003%/℃ at zero value, ±0.004%/℃ at full value

◆Safety overload: 150%

Speed Roller

The precise speed measuring roller (device) is installed on the conveyor frame and keeps running synchronously with the conveyor.

2017-03-28

WEIGHTING DEVICE

◆Comprehensive accuracy: ±0.01%;

◆The display is a four-line screen display, showing the instantaneous flow, cumulative amount, and operating parameters of the belt conveyor;

◆Scrolling menu, can be used for parameter input setting Chinese display, easy to operate;

◆Multiple calibration methods, automatic zero point and interval, automatic zero point tracking;

◆Communication interface (optional): standard RS~232C, RS485 interface.

◆If necessary, it can provide MODBUS, Ethernet communication and other functions.

◆The flow rate that can be set, the software PID adjustment, realizes the DCS automatic batching system control;

◆Multiple input and output ports;

◆Printing interface (printer optional).

◆Easy debugging: Chinese menu, automatic zero calibration, automatic interval calibration, fault self-diagnosis.

◆Data remote transmission:

a Analog quantity: real-time flow through the current signal (4-20mA, optional), the accumulated quantity is output to the remote place through the pulse signal

b digital: transmit all data to the host computer by means of communication;

◆Fault alarm: high flow alarm, low flow alarm, shutdown alarm, external alarm and other alarm signals;

◆Communication function: standard RS232 and standard RS485 interface, baud rate can be adjusted, address can be set, and multiple instruments can be networked;

◆Weighing instrument has two types: panel embedded and wall-mounted, which can meet the different requirements of various sites

Speed Sensor

◆It is connected to a special speed measuring device, which can eliminate the error caused by slippage between the friction wheel and the belt in the usual speed measuring device;

◆Airtight shell, with good shielding performance, good sealing performance, suitable for outdoor installation;

◆Brushless pulse generator, no need to adjust, calibrate or maintain;

◆The latest soft connection technology ensures the speed measurement accuracy more effectively;

◆Speed range: 0.05-4.0m/s

Weighting Sensor

The load cell is resistance strain gauge tension (pressure) force sensor.

◆Nonlinearity: less than 0.05% of rated output;

◆Repeatability: less than 0.03% of rated output;

◆ Hysteresis: less than 0.03% of rated output;

◆Temperature sensitivity: ±0.003%/℃ at zero value, ±0.004%/℃ at full value

◆Safety overload: 150%

Speed Roller

The precise speed measuring roller (device) is installed on the conveyor frame and keeps running synchronously with the conveyor.

2017-03-28

To order a belt scale, the following parameters are required:

◇Belt width B=______mm;

◇Maximum flow Q=______t/h;

◇ Belt conveyor speed v=______m/s;

◇Belt conveyor inclination =_____ degrees;

◇Length of belt conveyor L=______m;

◇Name of conveying material:____________;

◇Material bulk density:____________;

To order a belt scale, the following parameters are required:

◇Belt width B=______mm;

◇Maximum flow Q=______t/h;

◇ Belt conveyor speed v=______m/s;

◇Belt conveyor inclination =_____ degrees;

◇Length of belt conveyor L=______m;

◇Name of conveying material:____________;

◇Material bulk density:____________;